Kyakkyawan samfurin ba kawai ana sarrafa shi ba, har ma yana buƙatar jiyya daban-daban don cimma juriya na lalata, juriya, ƙayatarwa, da haɓaka rayuwar sabis.RCT MFG yana da shekaru masu yawa na gwaninta a cikin sarrafa CNC da sarrafa allura, kuma yana ba da jerin ayyuka daga aiki zuwa jiyya ta sama zuwa taro.Sabili da haka, ban da fasahar ƙirƙira, yana kuma da ƙwarewar ƙwarewa a cikin jiyya a saman.The data kasance surface jiyya tafiyar matakai sun hada da: zanen, Baking Paint, foda shafi, sandblasting, harbi ayukan iska mai ƙarfi, anodizing, lokacin farin ciki film anodizing, micro-baka anodizing, electroplating, electrophoresis, Laser engraving, siliki allo bugu, goga karfe, madubi polishing, rini, blackening, CD juna, etching, high sheki, etch juna, Epoxy, da dai sauransu, taimaka wajen sa your kayayyakin a cikin wani babban matakin.

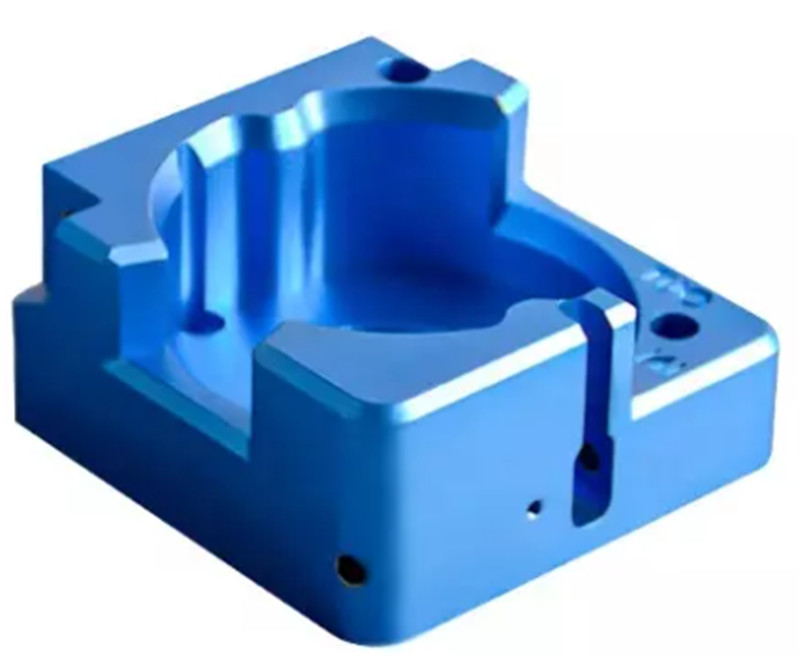

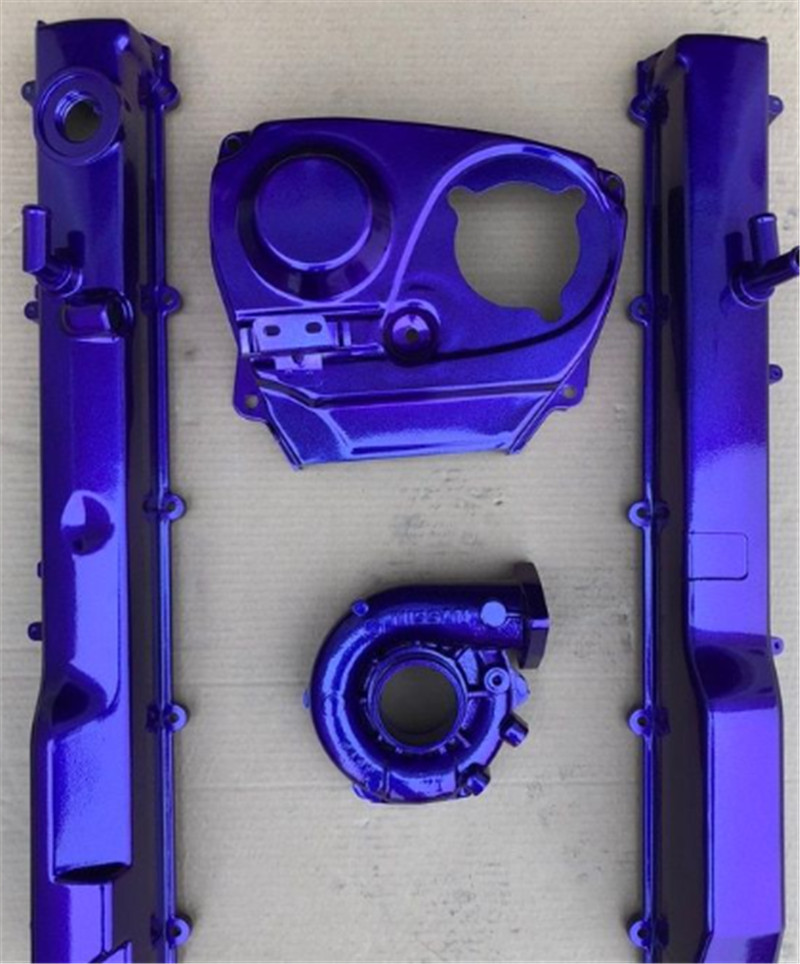

Anodizing

Yana da wani tsari na oxidation na electrolytic, wanda ke canza fuskar kayan zuwa fim mai kariya, yana sa ya zama da wuya a yi amfani da oxidize da lalata, tsawaita rayuwa da samun bayyanar launuka daban-daban.Ana amfani da magungunan anodizing da aka saba amfani da su zuwa: anodizing na kowa , baƙin ƙarfe anodizing, mai ƙarfi anodizing, lokacin farin ciki film anodizing, micro-arc hadawan abu da iskar shaka, da dai sauransu The kayan da za a iya oxidized ne: aluminum gami, magnesium gami, titanium gami, da dai sauransu.

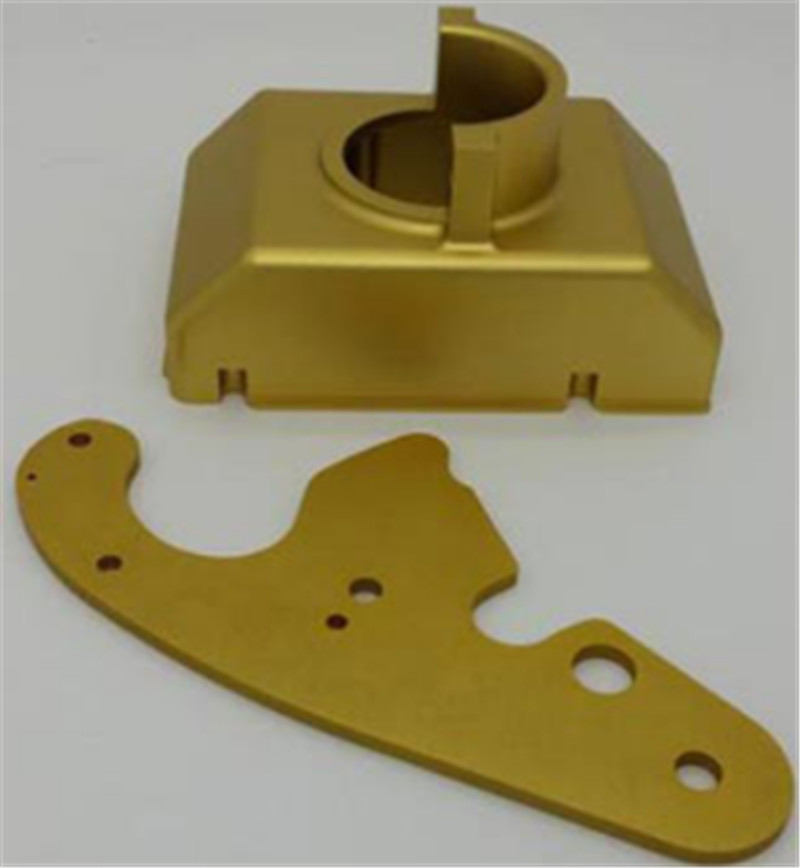

Electroplating

Babban tsari na electroplating shine a nutsar da sashin a cikin maganin gishiri na karfe a matsayin cathode, da farantin karfe a matsayin anode, da kuma wuce na yanzu don saka abin da ake so a sashin.Tasirin da ya dace da lantarki zai sa samfurin ku ya zama mafi girman salon zamani kuma tare da shi.Don ingantacciyar kasuwa, daidaitaccen lantarki ya haɗa da platin jan karfe, platin nickel, plating na azurfa, plating na zinariya, plating na chrome, galvanizing, tin plating, vacuum plating, da sauransu.

Electrophoretic shafi

Tare da ci gaba da haɓaka buƙatun masana'antu, fasahar suturar Electrophoretic na iya keɓance launuka daban-daban, kula da ƙyalli na ƙarfe da haɓaka juriya na lalata, wanda ke da ɗan tasiri akan daidaiton samfur.Kauri yana kusan 10-25um, kuma masu kauri kuma ana iya keɓance su

Abin sha'awa

Passivation, wanda kuma aka sani da chromate magani, wani pickling tsari ne wanda ke kawar da maiko, tsatsa, da oxides ta nutsewa ko tsaftacewa na ultrasonic.Ta hanyar maganin sinadarai na maganin wucewa, zai iya hana lalata kuma ya tsawaita tsatsa.Launi na fim ɗin wucewa zai canza tare da kayan daban-daban.Passiving ba zai ƙara kauri na samfurin ba, kuma babu buƙatar damuwa game da shi yana shafar daidaiton samfurin.

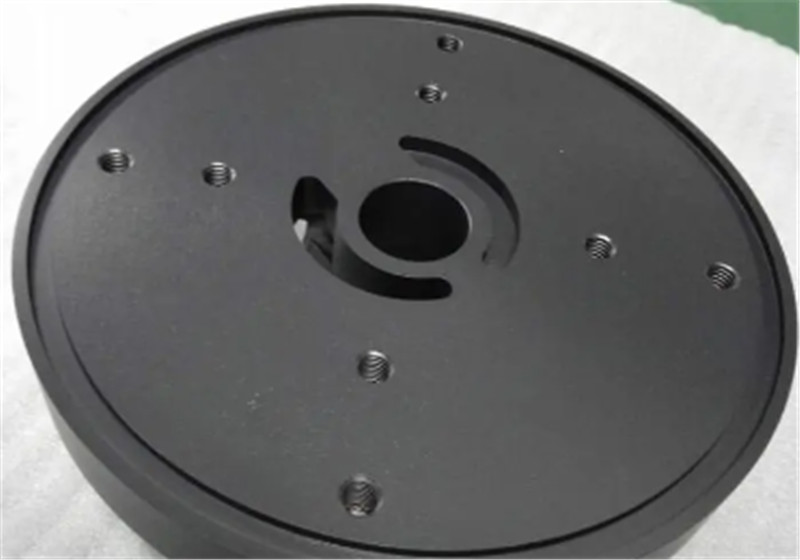

Baki

Baƙar fata kuma ana kiranta bluing.Ka'idar ita ce nutsar da samfurin a cikin maganin sinadarai mai ƙarfi mai ƙarfi don samar da fim ɗin oxide akan saman ƙarfe don ware iska da cimma manufar rigakafin tsatsa.Wannan tsari yana amfani da kayan karfe.

QPQ (Quench-Polish-Quench)

Yana nufin sanya sassan ƙarfe na ƙarfe iri biyu tare da nau'ikan wanka biyu tare da kaddarorin daban-daban, kuma yana haifar da dalilin inganta saman sassan sassan.Yana da juriya mai kyau, juriya ga gajiya, juriya na lalata da ƙananan nakasa.Wannan tsari yana amfani da duk kayan ƙarfe.

(Lura: Samfuran bakin karfe ba za a iya yin baki ba, kuma saman QPQ kawai zai iya yin baki)

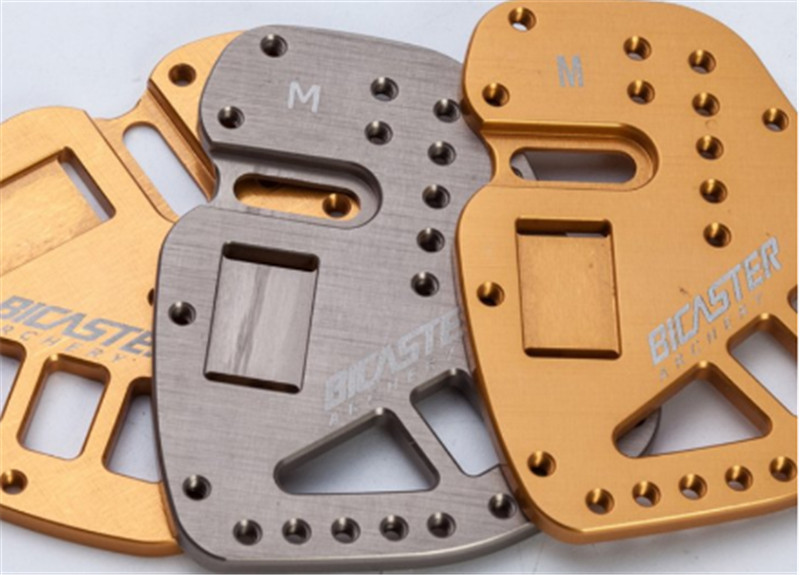

Laser engraving

Laser engraving, wanda kuma ake kira Laser marking, shi ne a saman jiyya tsari ta amfani da na gani ka'idojin samar da LOGO ko alamu a kan kayayyakin.A Laser engraving sakamako ne m, da surface ingancin ne high, kuma shi ne dace da kayayyakin Ya sanya daga daban-daban karfe da filastik kayan.

Buga allon siliki

Buga allo na siliki yana nufin cewa tawada yana canja tsarin zuwa samfurin ta fuskar allo.Ana iya daidaita launi na tawada bisa ga bukatun abokan ciniki.RCT MFG ya yi launuka 6 akan samfurin iri ɗaya, gami da baki, ja, shuɗi, rawaya da fari., kore.Idan ana son tasirin bugu na siliki ya kasance mai ɗorewa, Hakanan zaka iya ƙara Layer na UV bayan bugu na siliki don tsawaita rayuwarsa.Buga allon siliki ya dace da nau'ikan ƙarfe da kayan filastik, kuma ana iya haɗa su tare da jiyya na sama kamar oxidation, zanen, feshin foda, electroplating, da electrophoresis.

goge baki

gogewa shine don sanya samfurin ya zama kyakkyawa, mai jujjuyawa da kare saman.goge baki da bayyana gaskiya zabi ne mai kyau a gare ku.An raba polishing na kayan masarufi zuwa polishing na hannu, goge goge na inji, da goge goge na lantarki.Ana iya amfani da polishing Electrolytic don maye gurbin gyare-gyaren injiniya mai nauyi, musamman ga sassan da ke da sifofi masu rikitarwa da sassa waɗanda ke da wuyar sarrafawa ta hanyar gyaran hannu da hanyoyin injiniya.Ana amfani da polishing electrolytic sau da yawa don karfe, aluminum, jan karfe da sauran sassa.

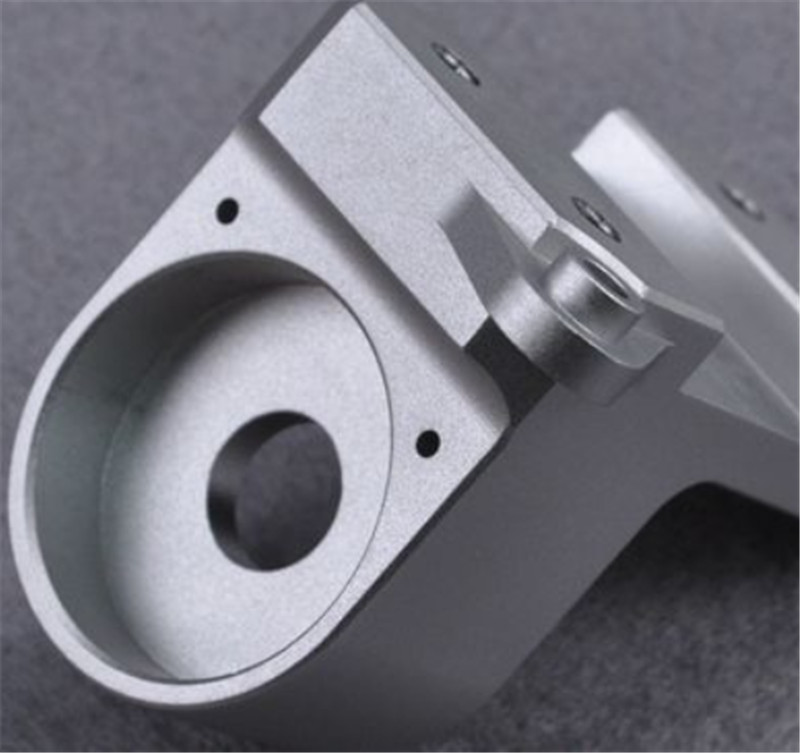

Karfe da aka goge

Ƙarfe da aka goge hanya ce ta jiyya ta saman da ke samar da layi akan saman kayan aikin ta hanyar bel ɗin da aka matse mai lebur da goga mara saƙa don cimma sakamako na ado.Yin gyaran fuska da aka goge zai iya nuna nau'in kayan ƙarfe, kuma yana ƙara zama sananne a rayuwar zamani.Ana amfani da shi sosai a cikin wayoyin hannu, kwamfutoci, na'urori masu aunawa, kayan daki, kayan lantarki da sauran harsashi.

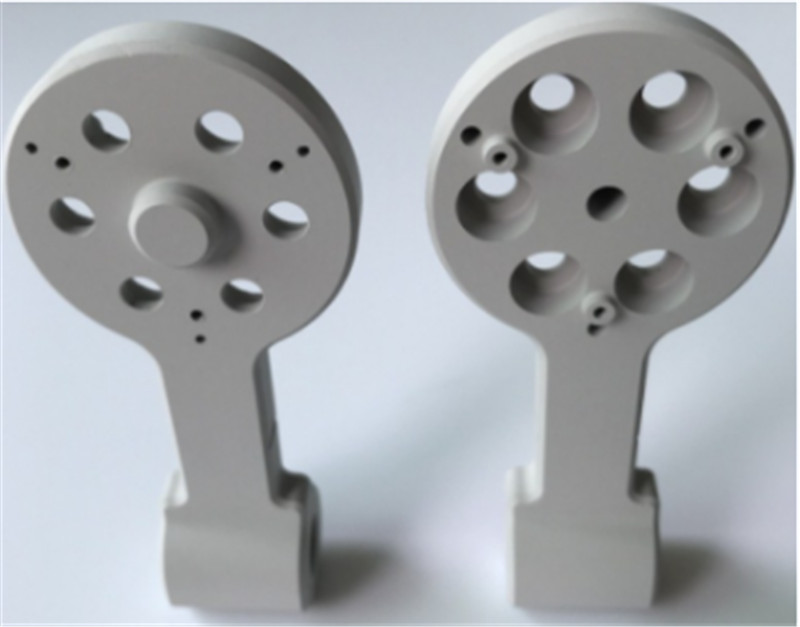

Fentin fenti da fesa foda

Fenti fenti da foda spraying ne biyu na kowa surface jiyya a hardware fesa sassa, kuma su ne da aka fi amfani da surface jiyya ga daidai sassa da kananan tsari gyare-gyare.Suna iya kare farfajiyar daga lalata, tsatsa, kuma suna iya cimma sakamako mai kyau.Dukansu spraying foda da zanen za a iya keɓance su tare da nau'i daban-daban (layi masu kyau, layi mai laushi, layin fata, da dai sauransu), launuka daban-daban, da matakan haske daban-daban (matte, lebur, babban mai sheki).

Yashi

Sandblasting yana ɗaya daga cikin jiyya da aka fi amfani da ita don samfuran kayan masarufi.Zai iya inganta tsabta da rashin ƙarfi, kuma yana ƙara mannewa da dorewa tsakanin samfurin da sutura.Saboda haka, yawancin jiyya na sama suna zaɓar yashi mai fashewa a matsayin riga-kafi.Irin su: yashi + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + kura, sandblasting + fenti, sandblasting + passivation, da sauransu.

Teflon spraying

Har ila yau ana kiran Teflon spraying, magani ne na musamman na musamman.Yana da halaye masu kyau na anti danko, rashin danko, juriya mai zafi, ƙarancin juriya, babban taurin, rashin rigar, da juriya na sinadarai.Sabili da haka, ana amfani dashi sosai a cikin masana'antar abinci, kayan abinci, kayan dafa abinci, masana'antar takarda, kayan aikin likita, samfuran lantarki da samfuran mota, kayan aikin sinadarai, da sauransu, kuma suna iya kare kayan daga lalata sinadarai don tsawaita rayuwar samfuran.

Etching

Etching shine dabarar cire abu ta amfani da halayen sinadarai ko tasirin jiki.Yawancin lokaci yana nufin etching, wanda kuma aka sani da photochemical etching, wanda ke nufin cire fim ɗin kariya na wurin da za a yi shi bayan yin farantin da aka yi da shi da haɓakawa, da kuma tuntuɓar maganin sinadarai a lokacin etching don cimma tasirin rushewa da lalata, haifar da sakamakon. concave-convex ko m gyare-gyare.

IMD

A cikin Mold Decoration (IMD) hanya ce mai tasiri mai tsada na ado sassa na filastik.Ya ƙunshi matakai guda huɗu: Bugawa, Ƙirƙira, Gyarawa da Gyaran allura.Kuma shahararriyar fasahar ado ce ta duniya.Fim ɗin ya taurare kuma a bayyane, Layer ɗin ƙirar bugu ta tsakiya, Layer ɗin gyare-gyaren allura na baya, da tsakiyar tawada na iya sa samfurin ya yi tsayayya da gogayya., Hana farfajiyar daga zazzagewa, kuma yana iya kiyaye launi mai haske kuma ba sauƙin fashewa na dogon lokaci.

Rubutun Pad

Pad printing, wanda kuma ake kira tampography ko tampo printing, tsari ne na bugu kai tsaye (gravure) inda na'urar siliki ta ɗauki hoton 2-D daga farantin bugu na laser (wanda ake kira cliché) kuma yana canja shi zuwa 3- D abu.Godiya ga bugu na pad, yanzu yana yiwuwa a buga kowane nau'in samfura masu siffa masu wahala kamar masu lankwasa (convex), m (concave), cylindrical, spherical, compound kusurs, textures, da sauransu waɗanda ba a samu tare da tsarin bugu na gargajiya ba.

Buga mai canza ruwa

Bugawar canja wurin ruwa wani nau'in bugu ne wanda ke amfani da matsa lamba na ruwa don sanya ruwa a cikin takarda canja wuri / fim ɗin filastik tare da alamu masu launi.Tsarin fasaha ya haɗa da samar da takarda bugu na canja wurin ruwa, jiƙa da takarda furen, canja wurin tsari, bushewa, da ƙãre samfurin.

Rubutun sarrafawa

Shafi mai ɗaukar hoto wani nau'in fenti ne wanda za'a iya amfani dashi don fesa.Yana iya gudanar da wutar lantarki bayan bushewa don samar da fim ɗin fenti, ta yadda zai kare tsoma bakin lantarki.A halin yanzu, ana amfani da shi a fannonin soja da na jama'a da yawa kamar na'urorin lantarki, na'urorin lantarki, jiragen sama, masana'antar sinadarai, bugu, da sauransu.

Lokacin aikawa: Afrilu-11-2023